Our customers often ask why they should choose our services. The answer lies in the precision and accuracy that laser manufacturing provides—qualities that are difficult to match with other manufacturing technologies.

We are dedicated to meeting any challenge related to your production requirements. Our expert team

pioneered the first laser job shop in Silicon Valley and is well-versed in the exacting standards

and tolerances of this high-tech industry.

We currently operate multiple CNC-controlled laser

systems—including three-axis, four-axis, and five-axis setups—capable of handling nearly any laser

cutting challenge. Additionally, we provide precision engraving and scribing solutions across a wide

range of materials.

Our advanced technology ensures high quality, exceptional precision, and

rapid turnaround times for all laser cutting and drilling applications.

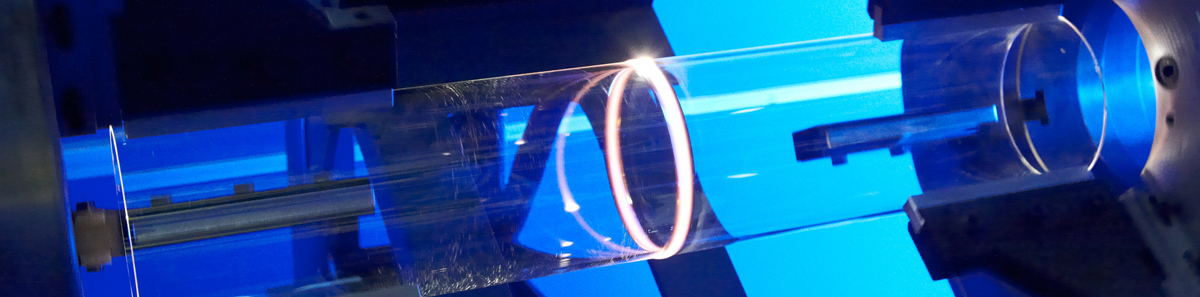

We have extensive experience in laser quartz cutting for the semiconductor industry, a

delicate process for which we are equipped to handle large diameter tubes and long-length injectors.

Our capabilities extend to laser cutting of any material compatible with CO₂ laser technology,

including quartz, ceramics, silicon carbide, metals and metal composites, synthetics, and natural

materials. Please contact our sales department to discuss your specific application.