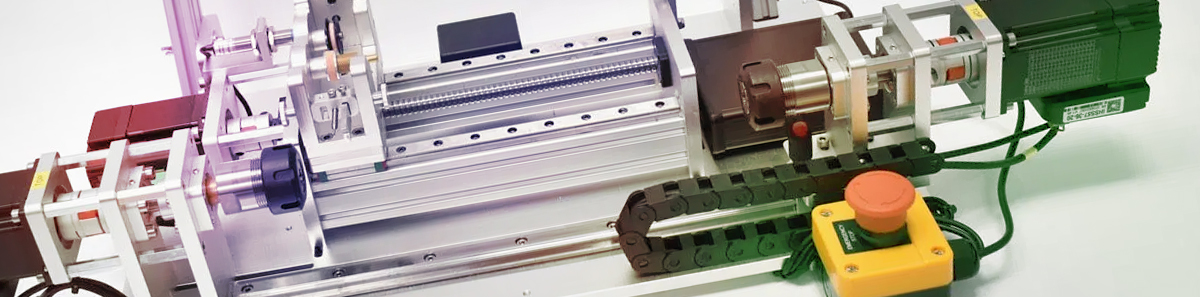

If your application requires custom CNC-controlled motion systems, we can design and build virtually any configuration, supporting up to seven axes.

The achievable resolution depends on the specific application, and we can incorporate rotary,

linear, and laser interferometer encoders as needed. We offer custom PC-based controllers upon

customer request.

We design and build custom CNC systems from new, state-of-the-art equipment tailored to your

specifications, incorporating motion control in any configuration and supporting all types of

lasers.

Additionally, we have the capability and resources to fabricate systems using refurbished

components, which can significantly reduce costs and lead times. We maintain an inventory of used

CNC machines that can be integrated into your custom motion control system, allowing us to pass

substantial savings on to you.

Custom CNC systems are often the ideal solution to meet your specific job demands. For repetitive

tasks requiring high throughput, a simple, purpose-built system can boost productivity and reduce

turnaround times.

We also recognize the importance of ease of training. More complex systems require more time and

resources to learn. By designing a system from the ground up based on your requirements, we deliver

a tool that precisely fits your needs, along with any necessary training.

Please contact our sales department for more information.